Brake motors are utilized in applications where stopping in a short amount of time is required. A normal motor will coast to a halt, where a brake will bring the motor to a complete stop within a reasonable amount of time. Heavy-duty loads, lifting applications (e.g. elevators), cranes (lifting, bridge movement), saws and grinders, conveyors, and other applications are all possible.

Because of our brake motors’ outstanding performance and long-term reliability, we are one of the best brake motor providers in the UAE.

The braking voltage is usually the same as the motor voltage (230 volts or 460 volts for motor and brake, respectively). The brake can be connected to the motor block to function in tandem with the motor, or it can be connected to a separate source to operate independently of the motor. (For example, an inverter application requires a “freewheel” motor). Alternate brake voltages (24VDC, 51VDC, 103VDC, and custom voltages to suit specific applications) are available as an option, allowing the brake to be operated independently by a different controller/source voltage. Hence there are different specifications and features available to choose from. We will give you the best and very reliable service.

Why Use Brake Motor?

Before moving forward, let’s discuss why we should use a brake motor and its advantages? First and foremost, the disc brake motor is a hybrid of a basic motor and an electromagnetic brake. When this motor loses control power, it will promptly brake and brake to prevent the heavy object from falling rapidly owing to power failure—dangerous behaviour combined with exceptional performance.

Second, this disc-brake motor’s circuit, silicon copper sheet, stator, and rotor are all made of high-quality materials, with substantial braking torque, precise positioning, and easy maintenance. Under frequent starting and load maintenance situations, it will not be easy to maintain. There was a pattern of the motor becoming burned out. (Of course, don’t misuse it!)

As a result, the electric chain hoist manufacturers mentioned above typically use a disc brake motor as the electric chain hoist electric motor.

Whether or not the electric chain hoist electric motor is utilized correctly directly impacts the electric chain hoist service life and our job efficiency.

Now the features are discussed below-

Motor Features

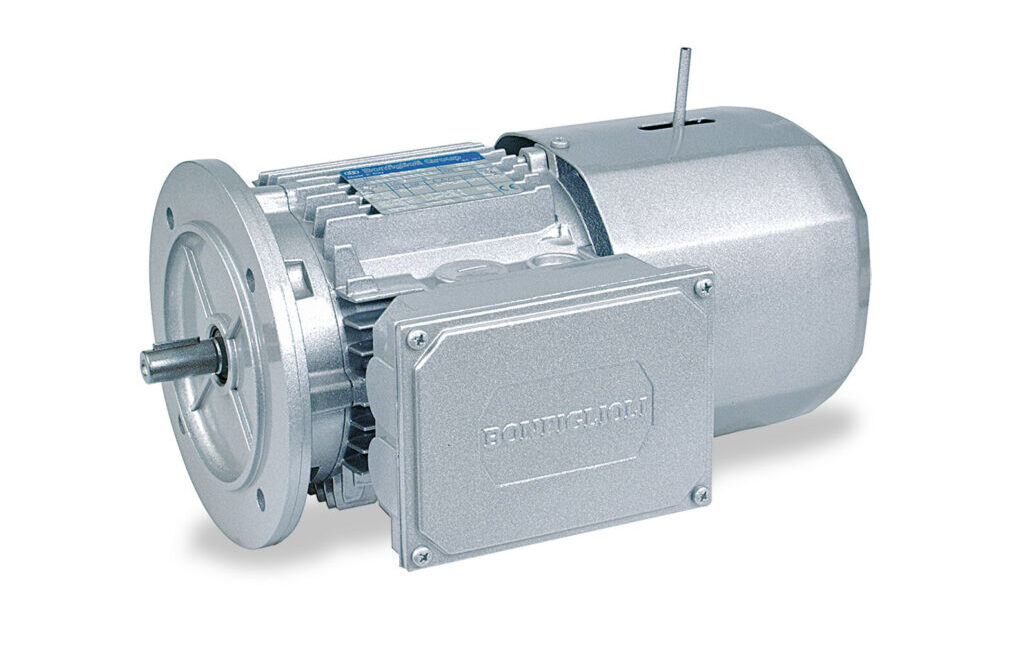

- Robust design and technology

- Proven reliability with long life service

- Great flexibility for your specific solutions

- You will find a wide variety of accessories and options

- High-quality procedures implemented from design to finished products

Brake Features

- Specially developed brake for highest function security

- Braking disc with low wear and less maintenance

- Easy installation and operation

Hence the brake motors are curated with the best features possible to meet the specifications and demands of our customers. We assure you of very reliable service, and we will try to provide you with the best assistance.